How is a steel quote constructed? Will there be other hidden costs? In this article, XTD Steel Structure will make a big list of materials to be prepared for the quotation and the content of the quotation to make the quotation more transparent.

Steel structure engineering has been widely used in modern industrial construction due to its durability and short construction period. However, the cost of steel structure engineering can also vary significantly due to differences in external conditions. This article will provide a clear summary of the composition of steel structure quotations.

1. Cost factors to be considered in the quotation

1.1. Material cost:

Steel is the main material of steel structure engineering, and its price fluctuates greatly due to the influence of the international market. The types, specifications, quality grades of steel, and the selection of auxiliary materials such as connectors, coatings, and fireproof materials will greatly affect the final overall project quotation.

1.2. Labor cost:

Design complexity The design complexity of steel structure engineering directly affects the material usage and construction difficulty. Complex designs may require more steel and sophisticated construction processes, increasing costs.

1.3. Installation cost:

The longer the construction period, the higher the labor costs, equipment rental fees, and other expenses will be. However, the length of the construction period is directly related to the cost.

1.4. Management cost:

Technical and management levels: Advanced construction technology and efficient management can reduce construction costs, material waste, and human errors, thus reducing construction costs.

2. Interpretation of the core elements of the quotation

2.1. The dominant factor of material cost

The price of steel varies with different types: for example, the prices of common structural steel, ordinary carbon structural steel, and low alloy structural steel are also different. For statistics, it is also necessary to analyze factors such as international iron ore prices and domestic steel production capacity.

2.2. Details of labor and installation costs

In the manufacture of steel structure engineering, various types of work are involved (such as riveters, welders, crane operators, and installers, etc.), and there are also technical requirements for workers’ proficiency and construction difficulty during operation (for example, high-rise steel structure welding requires certain technical requirements). The higher the proficiency of the workers, the higher the labor cost. At the same time, working hours and costs will also be affected. Let’s take a typical steel structure plant as an example. From the manufacture of steel structure components to the overall project installation, working hours will be involved, which will also involve the labor time required. After summarizing the labor time per ton of steel structure and multiplying it by the corresponding labor unit price, the proportion of total labor cost is calculated. (It is necessary to match the construction personnel’s work site map and the form of working time record)

2.3. Equipment and machinery use expenses

On-site installation machinery rental expenses: For tower cranes, truck cranes, elevators, and other necessary on-site machinery, according to the project installation height, span, and weight requirements, estimate the machinery rental time and calculate the rental cost per ton of steel structure.

3. Optimize project requirements and improve the cost-effectiveness of steel structure quotations

3.1. Quality and demand control and communication

High-quality materials and exquisite craftsmanship are extremely important for the durability and safety of steel structures, but they also increase costs. Therefore, during the design phase, the owner must communicate effectively with the designer to optimize the structure’s selection, control the necessary requirements, and avoid waste caused by the mismatch between expected and actual requirements.

4. Issues to note when requesting a quotation

4.1. the construction period requirement standard and estimated arrival time should be provided when consulting for a quotation.

4.2. The total amount of the project should be calculated by counting the number of works and multiplying the comprehensive unit price.

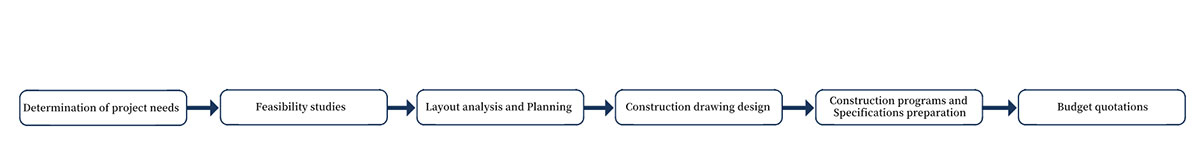

4.3. The necessary materials, such as design drawings and detailed drawings, should be prepared to facilitate a quick and relatively accurate quotation.

5. Conclusion

The key components, influencing factors, ways to obtain quotations, key project planning, materials, labor, machinery, and other costs per ton of steel structure quotation during manufacturing and installation, flexible use of price knowledge and accumulated project experience, and cost control and efficient work from planning to implementation of steel structure projects.